Berkeley Lab Computer Scientists Developing Tools to Reduce Greenhouse Gases at the Source

January 12, 2013

By John Bashor

Despite advances in alternative energy sources, the United States will continue to rely on coal-fired power plants to generate much of the nation’s electricity for the next 20 years or more. While coal is an economically viable fuel, its environmental cost is high—in 2011, coal accounted for 34 percent of the energy-related carbon dioxide (CO2) emissions in the United States.

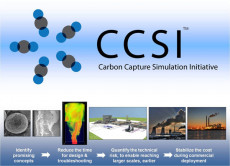

This is why a U.S. Department of Energy project, called the Carbon Capture Simulation Initiative (CCSI), is bringing together America’s national laboratories, industry and academic institutions, to develop and deploy state-of-the-art computational modeling and simulation tools to accelerate the commercialization of carbon capture technologies in power plants.

As part of this collaboration, computational researchers at Lawrence Berkeley National Laboratory (Berkeley Lab) are playing key roles in the development of the computational tools. This past October, CCSI released their first set of tools and models at a meeting with representatives from the 19 companies that are currently participating on its industry advisory board.

“This pre-release, a year ahead of the originally planned first release, is the result of intense industry interest in getting early access to the tools and the phenomenal progress of the CCSI technical team,” DOE’s National Energy Technology Laboratory (NETL) Director Anthony Cugini wrote in a letter to Energy Department Secretary Stephen Chu. “These initial components of the CCSI toolset provide new models and computational capabilities that will accelerate the commercial development of carbon capture technologies and, really, an incredibly broad range of technology development in general—power, refining, chemicals production, gas production to name a few.”

Because carbon capture systems are not yet required at any of the 600 plus plants across the country, CCSI works closely with industry to make the tools easier to adapt to existing design technologies. These tools would make it easier for utility companies to meet such requirements if and when they are enacted, and could help companies doing business in countries where controls are already in place. “CCSI brings together the best capabilities in scientific modeling and simulation at our national laboratories, universities, and industry, to help industry address this unprecedented challenge at low cost, in less time,” said Madhava Syamlal (NETL), Technical Director of the CCSI project, which is led by NETL.

Speeding Up Deployment of Carbon Capture Technologies

The broad goal of CCSI is to develop computational tools that will be used to accelerate the commercial development of advanced carbon capture technology. This includes (1) enabling promising concepts to be more quickly identified through rapid computational screening of devices and processes; (2) reducing the time to design and troubleshoot new devices and processes; (3) quantifying the technical risk in taking technology from laboratory scale to commercial scale; and (4) stabilizing deployment costs more quickly by replacing some of the physical operational tests with virtual power plant simulations. “The CCSI computational tools are delivering new capabilities for integrating multi-scale modeling, optimization and uncertainty quantification, which will significantly impact the way carbon capture processes are developed,” said David Miller of NETL, technical lead of CCSI. “These tools will ultimately enable smarter, more focused pilot and demonstration scale projects.”

“One of the goals is to accelerate the time needed to deploy carbon capture systems at coal-fired power plants, but it’s almost like walking a tightrope,” said Deb Agarwal, head of the Advanced Computing for Science (ACS) Department and Berkeley Lab’s CCSI lead for framework integration. “The corporations don’t have a lot of incentive to invest in this area yet, but they will need to be able to ramp up quickly if such systems are required.”

When completed, the CCSI Toolset will provide industry users with a comprehensive, integrated suite of scientifically validated models that enable optimization of design, assessment of uncertainty, and understanding of risks to support decision making capabilities. This set will also give them increased confidence in designs and reduce the risk associated with incorporating multiple innovative technologies into new carbon capture solutions.

The recent Toolset release included a number of integrated applications consisting of CCSI tools and commercial software. Paolo Calafiura leads the software engineering team of Keith Beattie, Abdelilah Essiari, Sarah Poon, and David Robertson, as well as collaborators Greg Pope (LNNL) and Tim Carlson (PNNL). They are implementing the CCSI web portal (www.acceleratecarboncapture.org) and software build, testing, and release processes. This first CCSI software release contained 19 new software packages and models, and the LBNL team orchestrated the testing of the manuals, tutorials, installers, and software and accomplished this on a tight schedule (six weeks) and on time.

For example, John Eslick at NETL and Jim Leek (LLNL) developed a library called "AspenSinter," which is used to integrate process models or flow sheets using AspenTech process modeling and flow sheet applications with the CCSI software framework. This has allowed the team to efficiently run and analyze half a million AspenTech simulations.

Meanwhile, Joshua Boverhof of CRD’s Advanced Computing for Science Department developed the Turbine Science Gateway (TSG), a code for running the AspenTech process simulation applications in parallel on cloud computing systems, clusters, or on standalone machines. The TSG implements the parallel simulations needed by uncertainty quantification and optimization. Boverhof incorporated an auto-scaling component, allowing TSG to take advantage of lower-cost, on-demand resources at Amazon Web Services to run tens of thousands of simulations together. He recently won honorable mention for TSG in a competition sponsored by Amazon.

Realizing the potential of CCSI depends on having an integrated carbon capture simulation environment that enables multi-scale simulations, uncertainty quantification, decision support, and optimization, all to interact, share data, and share results. In talking with industry partners, Agarwal said, "Many parts of the process are done separately, with very little carryover or connectivity, which can affect the time it takes to design a process. By integrating the steps, feedback can help quantify uncertainties in simulations and lead to improved tools." LBNL is the lead institution on the integration framework, data model, and data management development. Dan Gunter and Doug Olson of LBNL led the data model development to define the data interchange and storage formats.

An area where industrial researchers could benefit from CCSI modeling is in identifying promising adsorber materials—used in an adsorber designed to capture CO2 molecules before the flue gas exits a power plant through a smokestack. Ideally, this chemical sponge would be able to continuously remove CO2 from the plant’s emissions and capture it. In addition to CO2, the adsorber would also need to handle the water vapor in the flue gas. A group of materials known as zeolites appear promising for this application, but the current challenge is to identify the one that works best at the lowest cost. To do this the CCSI team is tapping into the materials database created by DOE’s Energy Frontier Research Centers, including the Center for Nanoscale Control of Geologic Carbon led by Berkeley Lab. Berend Smit, Maciej Haranczyk, Jihan Kim, Mahmoud Forrest Abouelnasr, and Kuldeep Jariwala have developed the calculations needed to help identify promising materials. The resulting database has been connected to the CCSI tools through the integration framework.

CRD staff working on CCSI are: Deb Agarwal (CCSI Integration Framework Task Lead), Paolo Calafiura (CCSI Software Development Support Task Lead), David Brown (LBNL Lab Lead), Keith Beattie (software build and test), Joshua Boverhof (Turbine Science Gateway), Abdelilah Essiari (software test), Daniel Gunter (data model), Douglas Olson (data model), Sarah Poon (user interface design), Maciej Haranczyk (EFRC database), and David Robertson (web portal development).

Other labs collaborating on CCSI are National Energy Technology (lead), Pacific Northwest, Los Alamos, and Lawrence Livermore national laboratories. Funding is currently provided through the Crosscutting Research Program of the U.S. Department of Energy’s Office of Fossil Energy. The project was started with funding under the American Reinvestment and Recovery Act (ARRA).

This is why a U.S. Department of Energy project, called the Carbon Capture Simulation Initiative (CCSI), is bringing together America’s national laboratories, industry and academic institutions, to develop and deploy state-of-the-art computational modeling and simulation tools to accelerate the commercialization of carbon capture technologies in power plants.

As part of this collaboration, computational researchers at Lawrence Berkeley National Laboratory (Berkeley Lab) are playing key roles in the management of the project and development of the computational tools. This past October, CCSI released their first set of tools and models at a meeting with representatives from the 19 companies that are currently participating on its industry advisory board.

“This pre-release, a year ahead of the originally planned first release, is the result of intense industry interest in getting early access to the tools and the phenomenal progress of the CCSI technical team,” DOE’s National Energy Technology Laboratory (NETL) Director Anthony Cugini wrote in a letter to Energy Department Secretary Stephen Chu. “These initial components of the CCSI toolset provide new models and computational capabilities that will accelerate the commercial development of carbon capture technologies and, really, an incredibly broad range of technology development in general—power, refining, chemicals production, gas production to name a few.”

Because carbon capture systems are not yet required at any of the 600 plus plants across the country, CCSI works closely with industry to make the tools easier to adapt to existing design technologies. These tools would make it easier for utility companies to meet such requirements if and when they are enacted, and could help companies doing business in countries where controls are already in place. CCSI is led by NETL.

Speeding Up Deployment of Carbon Capture Technologies

Within the next eight to 10 years, DOE aims to have widespread deployment of carbon capture and storage technologies. So two broad CCSI goals include: helping existing coal-fired facilities incorporate carbon capture technologies into their operations, and reducing the prototyping time and iterations required during the testing and development phase of a new power plant design. The latter goal would ideally accelerate the deployment of next-generation power plants with carbon capture technologies. Currently, commercial deployment of these technologies takes between 20 to 30 years. This is primarily because engineers need to produce progressively larger prototype scale plants, about four to six prototypes, before reaching a commercial scale pilot plant. But using the CCSI tools, researchers hope to reduce this development time by five years.

“One of the goals is to accelerate the time needed to deploy carbon capture systems at coal-fired power plants, but it’s almost like walking a tightrope,” said Deb Agarwal, head of the Advanced Computing for Science (ACS) Department and Berkeley Lab’s CCSI lead for framework integration. “The corporations don’t have a lot of incentive to invest in this area yet, but they will need to be able to ramp up quickly if such systems are required.”

When completed, the CCSI Toolset will provide industry users with a comprehensive, integrated suite of scientifically validated models that enable optimization of design, assessment of uncertainty and understanding of risks to support decision making capabilities. This set will also give them increased confidence in designs and reduce the risk associated with incorporating multiple innovative technologies into new carbon capture solutions.

The recent Toolset release included a number of integrated applications comprised of CCSI tools and commercial software. For example, John Eslick at NETL developed a library called "sinter," which he used to run process models or flow sheets using AspenTech process modeling and flow sheet applications out of Microsoft Excel. Although using Excel to run AspenTech applicatons is fairly common, the method only allows the user to compute on one machine.

Meanwhile, Joshua Boverhof of CRD’s Advanced Computing for Science Department developed the Turbine Science Gateway (TSG), a code for running the AspenTech applications in parallel on cloud computing systems, clusters or on standalone machines. Boverhof incorporated an auto-scaling component, allowing TSG to take advantage of lower-cost, on-demand resources at Amazon Web Services to run tens of thousands of simulations together. He recently won honorable mention in a competition sponsored by Amazon for TSG.

Realizing the potential of CCSI depends on having an integrated carbon capture simulation environment that enables multi-scale simulations, uncertainty quantification, decision support, and optimization, all within an integrated framework. In talking with industry partners, Agarwal said, many parts of the process are done separately, with very little carryover or connectivity, which can affect both the accuracy of the models and the time it takes to create them. By integrating the steps, feedback can help reduce uncertainties and lead to improved tools.

One area where researchers could benefit from this modeling is evaluating adsorber materials—a device that could be implemented on a smokestack to soak up CO2 molecules as they travel up the stack. Ideally, this chemical sponge would be able to continuously remove CO2 from the plant’s emissions and capture it. In addition to carbon, this absorber would also need to handle water vapor, which is also in the exhaust plume. A group of metals known as zeolites appear promising for this application, but the current challenge is to identify the one that works best at the lowest cost. To do this the CCSI team is tapping into the materials database created by DOE’s Energy Frontier Research Centers, including the Center for Nanoscale Control of Geologic Carbon led by Berkeley Lab. Berend Smit, Maciej Haranczyk, Jihan Kim, Mahmoud Forrest Abouelnasr and Kuldeep Jariwala have developed the needed capabilities and connected the resulting database to the CCSI tools.

According to Agarwal, the software development environment in CCSI needs to provide comprehensive development support and incorporate comprehensive licensing, testing, versioning, bug tracking, build, packaging, and test tools. Paolo Calafiura leads the software engineering team of Keith Beattie, Abdelilah Essiari, Sarah Poon and David Robertson. They are implementing the CCSI web portal and software testing and release processes. The Turbine Science Gateway developed by Boverhof implements the parallel simulations needed by uncertainty quantification and optimization. Dan Gunter and Doug Olson of ACS led the data model development to define the data interchange and storage formats.

Computational Research Division staff working on CCSI are: Deb Agarwal (CCSI Integration Framework Task Lead), Paolo Calafiura (CCSI Software Development Support Task Lead), David Brown (LBNL Lab Lead), Keith Beattie (software build and test), Joshua Boverhof (Turbine Science Gateway), Abdelilah Essiari (software test), Daniel Gunter (data model), Douglas Olson (data model), Sarah Poon (user interface design), Maciej Haranczyk (EFRC database), and David Robertson (web portal development).

Other labs collaborating on CCSI are Pacific Northwest, Los Alamos and Lawrence Livermore national laboratories.

About Berkeley Lab

Founded in 1931 on the belief that the biggest scientific challenges are best addressed by teams, Lawrence Berkeley National Laboratory and its scientists have been recognized with 16 Nobel Prizes. Today, Berkeley Lab researchers develop sustainable energy and environmental solutions, create useful new materials, advance the frontiers of computing, and probe the mysteries of life, matter, and the universe. Scientists from around the world rely on the Lab’s facilities for their own discovery science. Berkeley Lab is a multiprogram national laboratory, managed by the University of California for the U.S. Department of Energy’s Office of Science.

DOE’s Office of Science is the single largest supporter of basic research in the physical sciences in the United States, and is working to address some of the most pressing challenges of our time. For more information, please visit energy.gov/science.